Recently, HollySys received a letter of thanks from Weifang Hongrun Petrochemical Technology Co., Ltd. The letter stated that Hongrun Petrochemical Technology adopted HollySys' Industrial Internet platform in its smart factory project, which was integrated with its information system to further streamline the data process and realize the efficient office work of the management and the real-time monitoring of the on-site construction situation during the construction period of the project. With the help of HollySys' project team, Hongrun Petrochemical Technology has built a "Platform+Tools+App" innovative technology model and fully integrated new technologies with the traditional industry to give the full play to the actual value of the innovative smart factory. Moreover, the letter contains the full recognition and high praise for the innovative scheme, highly professional skills, high-quality and efficient services, and extremely responsible attitude toward work of HollySys' project team.

Create a Powerful Alliance to Jointly Promote the New Development of the Industry

In April 2020, HollySys signed an agreement with Hongrun Petrochemical Technology on the supporting project for the processing of intermediate raw materials, achieving a breakthrough in the performance of the main equipment in the petrochemical industry. The two sides took this as an opportunity to establish a partnership. In May 2020, they signed a strategic cooperation agreement on joint innovation to improve the overall operational efficiency of large petrochemical complexes and help the digital and intelligent transformation and upgrading of China's petrochemical industry. In July 2020, they signed an agreement for the innovative smart factory project and announced the official start of the project. This also lays a solid foundation for the long-term cooperation between the two sides in information and intelligent construction.

Stay Focused to Build a New Model for the Industry

The smart factory project of Hongrun Petrochemical Technology is a major innovative project of HollySys in smart factories, which was jointly carried out by Weifang Liaison Office, the Solution Center, and the Digital Factory Application Department of Hangzhou HollySys Automation Co., Ltd., a subsidiary of HollySys Group. The project, based on HollySys' Industrial Internet platform, aims to establish a factory-wide data center, build an integrated intelligent management and control platform, effectively integrate the data on the management and control layers, establish a whole-process and full-life-cycle management and control model based on the data of each business department, and finally enable intelligent data collection, analysis and decision-making. Moreover, in order to ensure the workplace safety of the petrochemical industry, an integrated intelligent environmental security monitoring system was established to generate escape routes intelligently, thus ensuring the safety of factory workplace and employees.

During the implementation of the project, the HollySys project team overcame many difficulties such as the tight schedule and the epidemic, and all departments worked together to actively allocate resources and went through all phases of the project including preliminary investigation, demand analysis, project planning, project implementation, technical development, and commissioning & optimization. Finally, we have witnessed every milestone and breakthrough of the project together with the user side and achieved the universal recognition from the user.

Adopt Hard & Core Technology to Facilitate Intelligent Development

Establish a Factory-wide Data Center to Integrate Data Resources

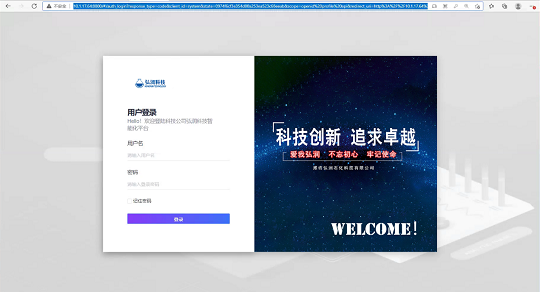

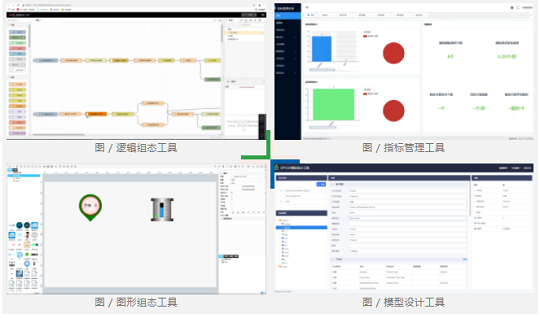

The first phase of the smart factory project set up by Weifang Hongrun Petrochemical Technology Co., Ltd. was based on the latest Industrial Internet platform architecture, and successfully applied the "Platform+Tools+App" innovative technology model.

Figure/Login Interface of the Integrated Intelligent Platform of Hongrun Petrochemical Technology

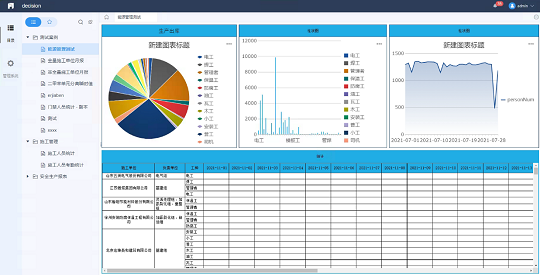

Intelligent Applications and Intelligent Decision-making

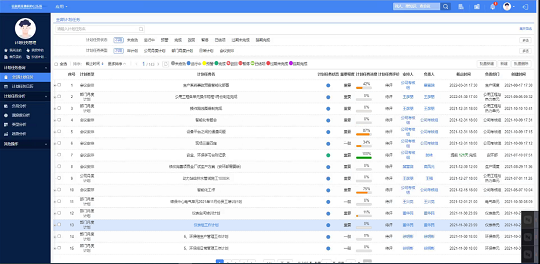

Scheduled Task Management Application

This application can arrange schedules for each department and each person as required, show calls on the calendar at any time, and provide real-time monitoring, management, and deployment. Moreover, it can provide intelligent analysis of each person's workload, generate related trends, reasonably adjust data, give satisfaction, make the management more humanized, and realize the refined management of personnel.

Figure/Scheduled Tasks

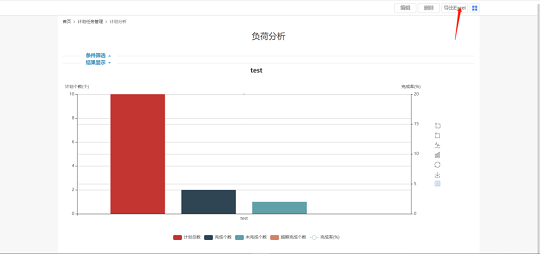

Figure/Load Analysis

Internal Marketization Application

The factory can generate decision-making opinions intelligently and suggestions on output, yield, raw material purchase, product export, etc. based on the processing, optimization, association, and analysis of data pertaining to the products, sales, inventory, and costs of various departments and units, thus providing reference for enterprises.

Figure/Comprehensive Analysis of Internal Marketization

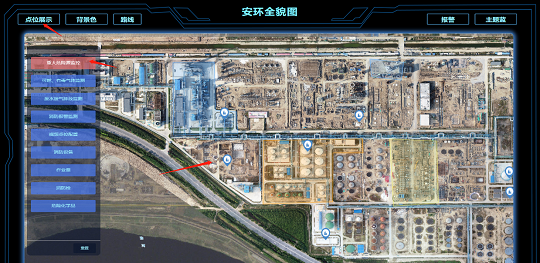

Secure the Industrial Journey

Integration of Intelligent Security, Management and Control

The real map of the Hongrun Petrochemical Technology factory is used to achieve integrated multi-layer display. The map model allows graphical display of functions like the monitoring of major hazards, monitoring of flammable, explosive, toxic and harmful gases, detection of waste water and exhaust gas, detection of fire alarms, configuration of video points, fire-fighting equipment, restricted space safe operation permit and safe fire operation permit. It allows adding, deleting, modifying and checking the map coordinates and basic information of the risk points for flammable, explosive, toxic and harmful gases, and supports operations such as batch deletion and hazard reminders. Moreover, it allows adding, deleting, modifying and checking the map coordinates and basic information of the risk points for serious hazards, and supports operations such as batch deletion and hazard reminders. In the case of a dangerous situation such as fire or leakage of toxic and harmful gases in the factory, the optimal escape route for personnel is intelligently generated.

Platform-independent App to Provide On-Site Control

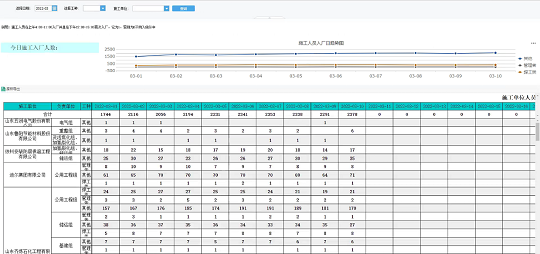

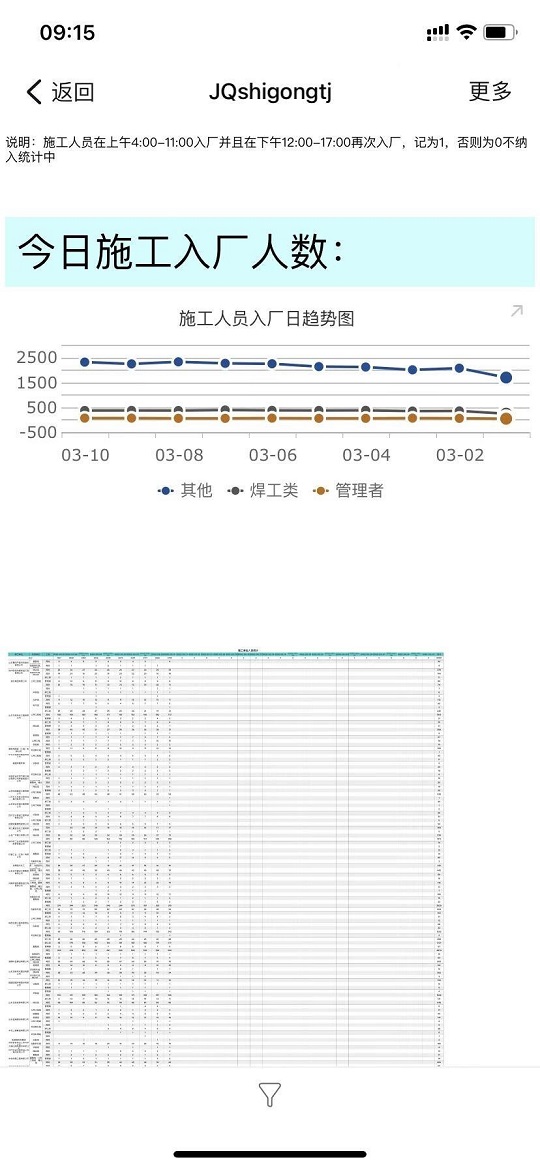

Construction Worker Statistics

The platform-based tool allows factory management personnel to configure the construction work statistics application with zero code. When employees enter the factory, this application can be associated with factory personnel data from the facial recognition system of access control to collect personnel statistics automatically by position, date, gender, age, identity, etc., so that the factory can well know the factory personnel information.

Production Report

Subject to the production requirements of the factory, relevant management personnel can configure the required production report application with zero code by using platform tools, importing data from data points, working out index formulas, and independently designing reports. After being entered in the mobile terminal, the data is available for statistics and analysis in the data center of the platform. Finally, the required content is displayed in the platform application.

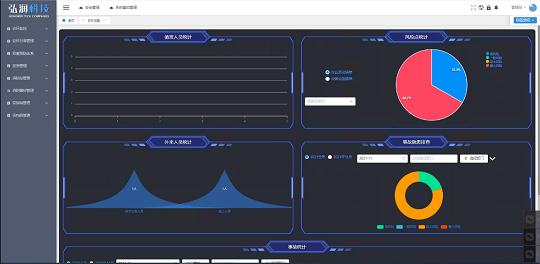

Smart Visual Large Screen to Provide Smart Management

Based on the integration, optimization, analysis and decision-making by the platform, the smart visual large screen can be used to show information such as safety, environmental protection, energy, planning, production, resources, cost, and market, thus enabling intelligent assisted decision-making.

In the future, HollySys will continue to pursue innovation-driven development, embrace the philosophy of "Customers in Mind with Sincerity", promote digital and intelligent upgrading for users, and work with users to build sample projects of smart factories in the industry.