At 15:05 on January 12, 2022, Unit 5 of Datang Anhui Luoneng Power Generation Co., Ltd. (hereinafter referred to as Datang Luohe) was successfully put into full-load trial operation after comprehensive upgrading and transformation, marking the successful operation of Unit 5 of Datang Luohe Power Plant. The first set of HollySys HOLLiAS MACS IC fully independent controllable DCS realizes the DCS+DEH whole plant integrated operation in ultra-supercritical units above 600 MW, providing a model project for the localization transformation of large thermal power units and setting a new industry benchmark.

Promoting Localization with Innovative Technology

Unit 5 of Datang Luohe was first put into operation in 2008 using DCS and DEH of foreign brands. During the transformation, HollySys HOLLiAS MACS IC fully Independent and Controllable DCS was used for revamping DCS of Unit 5 (including DEH and ETS) and DCS of common system of Unit 5 and Unit 6.

The total I/O number for the Project is over 30,000, and a total of 33 pairs of controllers have been configured to complete various functions such as DAS, MCS, SCS, FSSS, ECS, ETS, and DEH of the unit. On August 30, 2021, the factory acceptance was completed for the Project. On September 25, 2021, the site restoration was completed. On October 25, 2021, the common system was put into use. On November 26, 2021, the Project passed the on-site performance and function test organized by the expert group of the Power Generation Special Committee of the Chinese Association of Automation. On December 8, 2021, the Project passed the hydrotest. On December 20, 2021, the pipe purging was completed. On January 4, 2022, the turbine was started and reached the fixed speed of 3,000 rpm. On January 8, 2022, the unit successfully synchronized with grid. On January 12, 2022, the unit completed the full-load trial operation.

Independent and Controllable, Secure and Trusted HOLLiAS MACS IC DCS

HollySys HOLLiAS MACS IC Independent and Controllable DCS is an integrated management and control platform for the industrial site, integrating the functions of DCS, SIS/CCS, PLC, SCADA, and industrial software. It is of ultra-large-scale system design, and supports the integration of up to 128 domains, with each domain supporting up to 1.2 million tags and 64 control stations, and with each control station supporting up to 360 IO facilities. It has a response time shorter than 30 ms, fully meeting the high reliability and high safety requirements of ultra-large-scale refining-chemical projects.

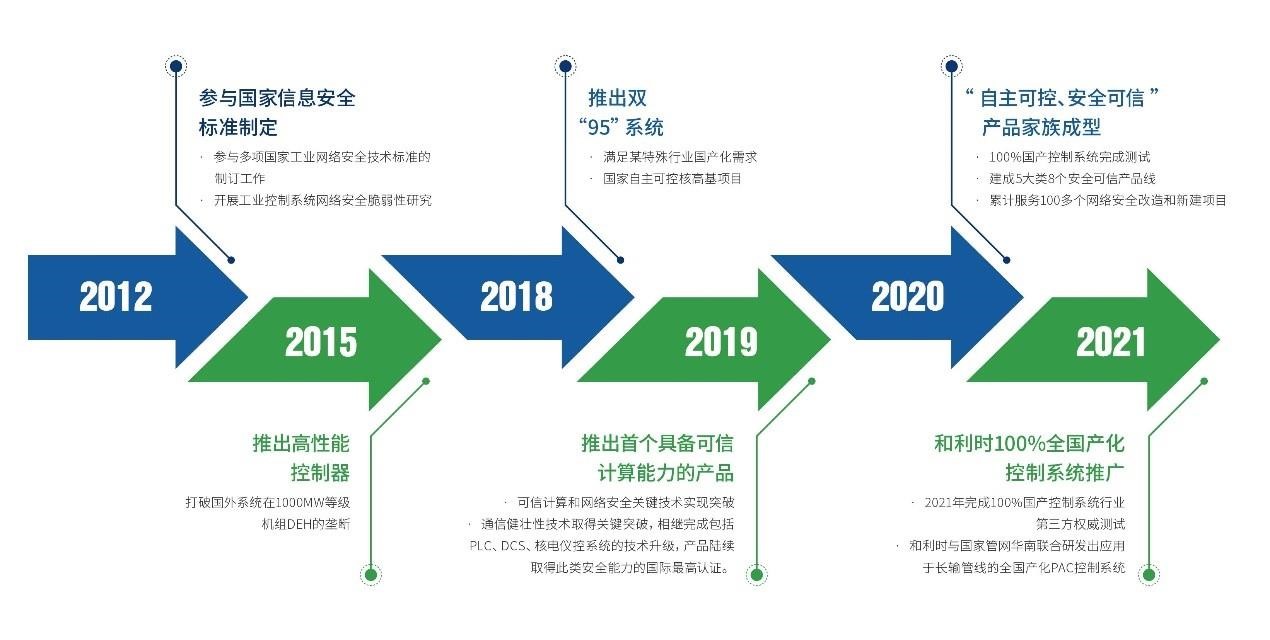

The system is the latest achievement of the deep integration of information security technology and localized control technology independently developed by HollySys and has three characteristics, namely software cross-platform, independent and controllable, and secure and trusted.

(1) All system software is cross-platform-compatible at the source code level., and one set of software source code is adapted to the compilation and construction of various operating systems, thus realizing cross-platform/cross-language data exchange. The system can easily be deployed on various different operating system platforms, thus facilitating the upgrading and transformation for installed systems.

(2) All system components are made in China, the system software is independently developed based on the operating system developed in China, and the platform adopts OT/IT deep integration technology to realize the integration of management and control. It can be said that the software and hardware of the system platform are fully domestic and independent and controllable.

(3) The main control unit of the system has a built-in independent and trusted security protection system, which improves the technical level of trusted computing in the field of industrial embedded control. The system is the first endogenous security DCS control system and has several built-in security audit and data encryption algorithms, meeting the requirements for classified protection of information security at Class III.

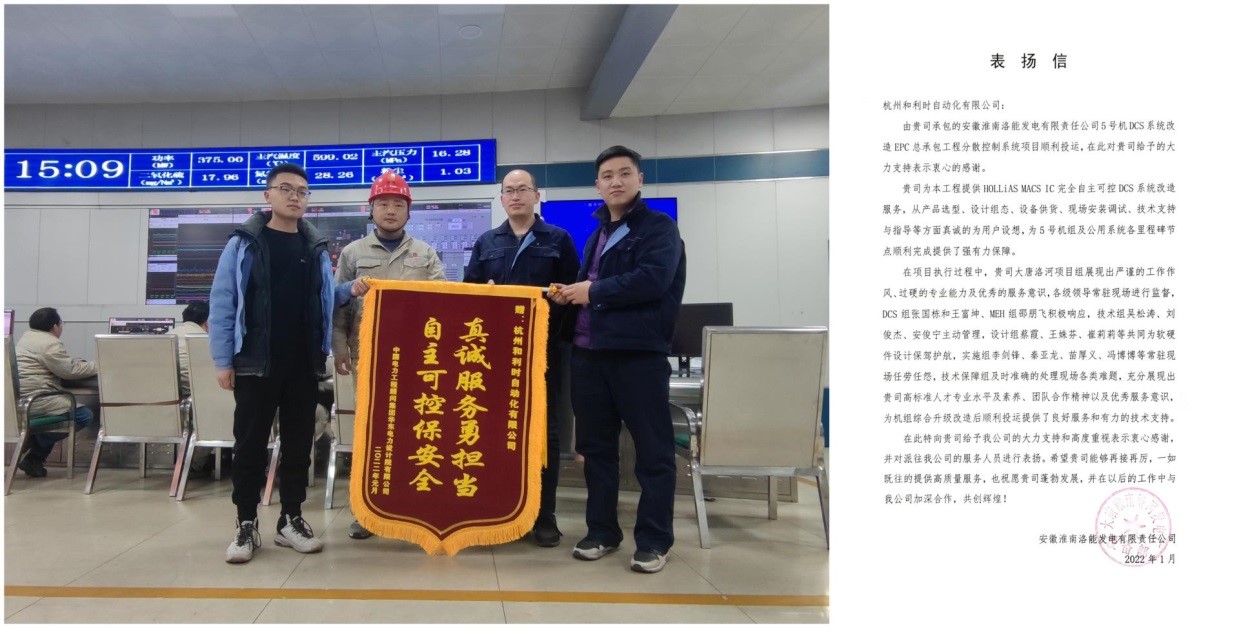

Improvement of Quality and Efficiency Recognized by the Users

Upon the establishment of the Project, HollySys dispatched excellent personnel from various departments to form the HollySys Project Team. Since the Project was put into operation, the HollySys system has operated stably, safely, and reliably, gaining the recognition of its users. Datang Luohe Power Plant and the EPC Contractor (East China Electric Power Design Institute) presented a banner for appreciation to HollySys in recognition of the quality products and excellent skills of HollySys. They have also spoken highly of the working attitude, high sense of responsibility and service spirit of the HollySys Project Team. The successful application of HollySys HOLLiAS MACS IC Independent and Controllable DCS in ultra-supercritical units above 600 MW is the perfect combination of chips, database, operating system, industrial software, automation technology, and large-scale thermal power industry technology in the independent industrial field. The system helps China break free from the dependence on foreign core technology for industrial control systems, solves problems such as supply chain safety, information security, functional safety, and intrinsic safety of the traditional industrial control systems, realizes full localization upgrading and transformation of large-scale industrial control systems, and improves the technical level of DCS in the power generation field of China, which is all of great significance for ensuring China’s national energy security.

HollySys will use this breakthrough as an important milestone to promote localization, make unremitting innovation and bold exploration, empower the industry with independent and controllable as well as secure and trusted products, technologies and solutions. HollySys will also utilize the efficient and easy-to-use integrated platform to help the users achieve a significant improvement in engineering efficiency, provide digital services to ensure the smooth operation of the users' systems and equipment, and continuously ensure the national industrial security.